Quality Checker SG

The Quality Checker reliably carries out the final check of your monolithic glass for quality and dimensions. The place of use is, for example, in the cutting area behind the automatic breakage or in a separate inspection conveyor, for example for shower doors or laminated glass. There, in addition to typical optical defects such as scratches, bubbles or inclusions, it can also check the contours, hole positions or cutouts. At the same time, the system documents all quality-related test results. In this way you reduce your complaint costs to a minimum, reliably secure your delivery quality promises and are well prepared in the event of an emergency.

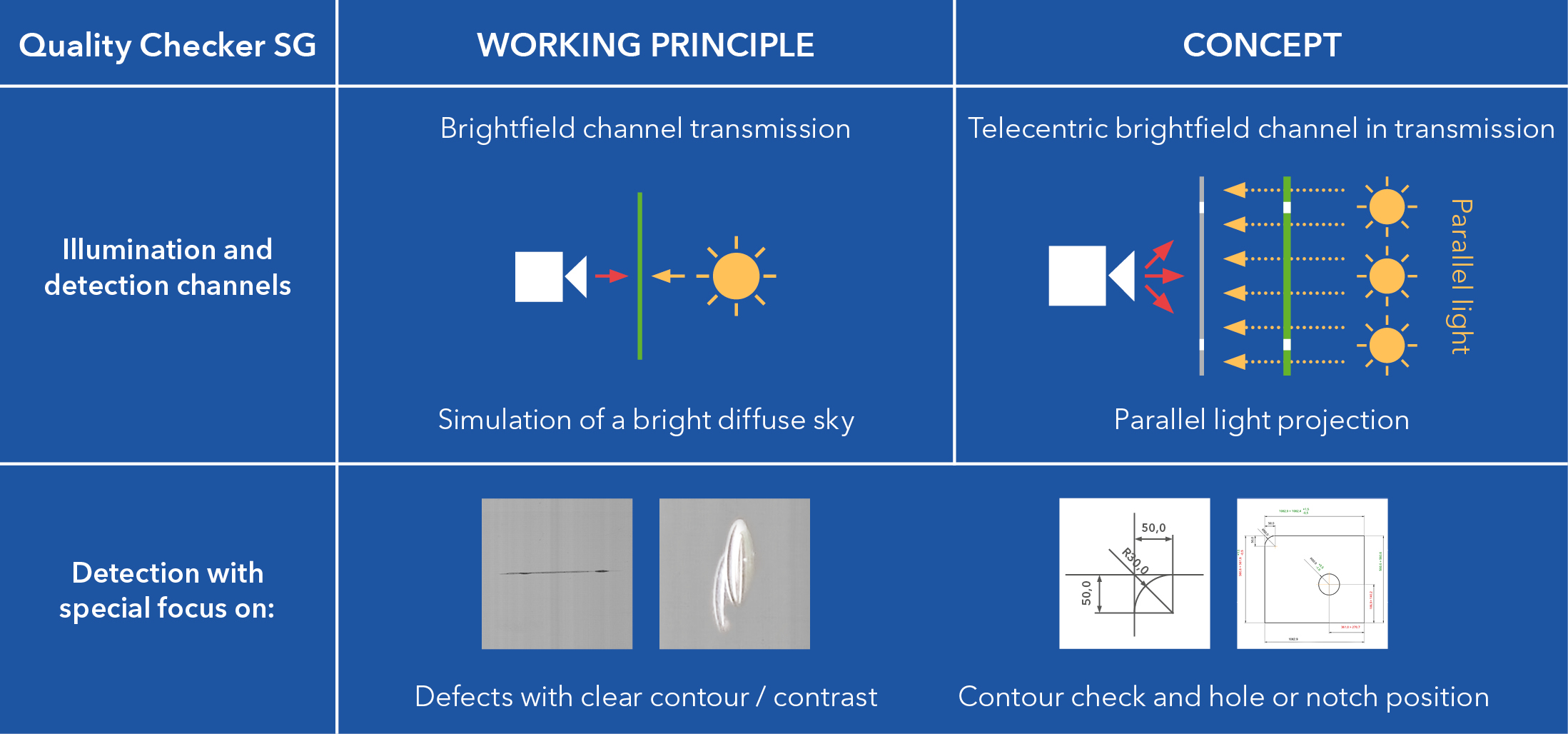

The channels used

The patented Telecentric Brightfield Channel of the Quality Checker Series is an evolution of the brightfield channel that you have long known as the base channel for the Quality Scanner. Despite the camera opening angle, it allows the pane to be viewed exactly perpendicularly, which is particularly necessary for measuring the contour, the position and diameter of holes, as well as the positions and geometries of cutouts or the detection of chips.

The testing processes

The perpendicular viewing on the pane is achieved by using a special lens technology that directs parallel light onto the pane to be tested. When the light passes through, the detected defects, contours, drill holes and cutouts create a two-dimensional image through a parallel projection onto a film-like diffusor between the glass and the camera. The camera picks up the details from this diffusor. With this patented process, the camera can take all the details of the three-dimensional glass, including the glass defects, drill holes and cut-outs from a two-dimensional surface, and so carry out precise measurements and check of the dimensions.

Area of application

- In the cutting area behind the automatic breakage

- In a separate test track behind a washing machine for testing against a dxf

Focus

- High contrast defects (bubbles, inclusions, scratches, pewter, etc.)

- Chips

- Determination of faulty hole positions and diameters

- Determination of incorrect position and geometry of cutouts

Modularly expandable

- Only brightfield channel (according to standards, e.g. ASTM C1036 or EN 1279 I)

Options to

- Improvement of the workflow (e.g. traffic lights, second operator station, etc.)

- Support for automation (connection to lines, ERP or PPS systems)

- Adaptation to special lines (special glasses)

- Storage and use of data (dashboard, reports, archive)

Technical specifications

Unit height/width |

Up to 3.30 m as standard |

Design |

Horizontal or vertical |

Maximum glass sizes |

3.30 m x 6.00 m |

Glass types that can be tested |

Float, tinted glass, tempered, laminated, LowE, sun protection glass, etc. |

Glass thicknesses |

Up to 60 mm – optionally thicker |

Transport speed |

up to 20 m/min |

FAQ

-

The Quality Checker SG must receive a dxf before the glass runs through the scanner. A connection to your ERP or PPS system is therefore necessary. The glass that runs through the scanner after the data has been received is compared with the dxf in a tolerance field specified by you. The test results are displayed in such a way that tolerance violations appear in red and so are quickly recognizable.

-

The accuracy of a measurement depends on the interaction of the transport and the optical control element. Accordingly, the Quality Checker SG needs a glass transport that is precise and tailored to the intended use, which is not usually the case with a typical roller conveyor. Depending on the tolerance requirements of the measurement, a new, suitable belt conveyor must be provided. In this case, please ask us for both the Quality Checker SG and the suitable belt conveyor.

-

The need to measure the drill holes and cutouts requires a parallel light projection onto a two-dimensional diffusor with a viewing angle of 0°. The diffusor is designed to block side light to not allow distortion of the parallel light projection. However, this would also block the light from the side of the darkfield or reflection channel of a Quality Scanner. A direct combination within a single device is therefore physically not possible.

-

In the Quality Checker series as well as in all other Viprotron scanners, you can freely store different quality levels and recipes.

Facesheet Quality Checker SG

The most important information and advantages of the Quality Checker SG at a glance.

Factsheet Inspection Systems

The advantages of our scanner systems at a glance. Because the higher quality of your glasses makes the difference.

Contact

You would like to coordinate a project with us or have questions about products and services? Then simply call us or send us an e-mail. We are looking forward to your message!

Contact details

Viprotron GmbH

Ostendstraße 17

64319 Pfungstadt

Germany

- Phone number

- +49 6157 986 380

- info@viprotron.de

Viprotron North America Inc.

7501 S. Jackson Gap Way

Aurora CO 80016 – USA

- Phone number

- +1 313 384 3855

- ric.schmidt@viprotron.com