ECO Scanner

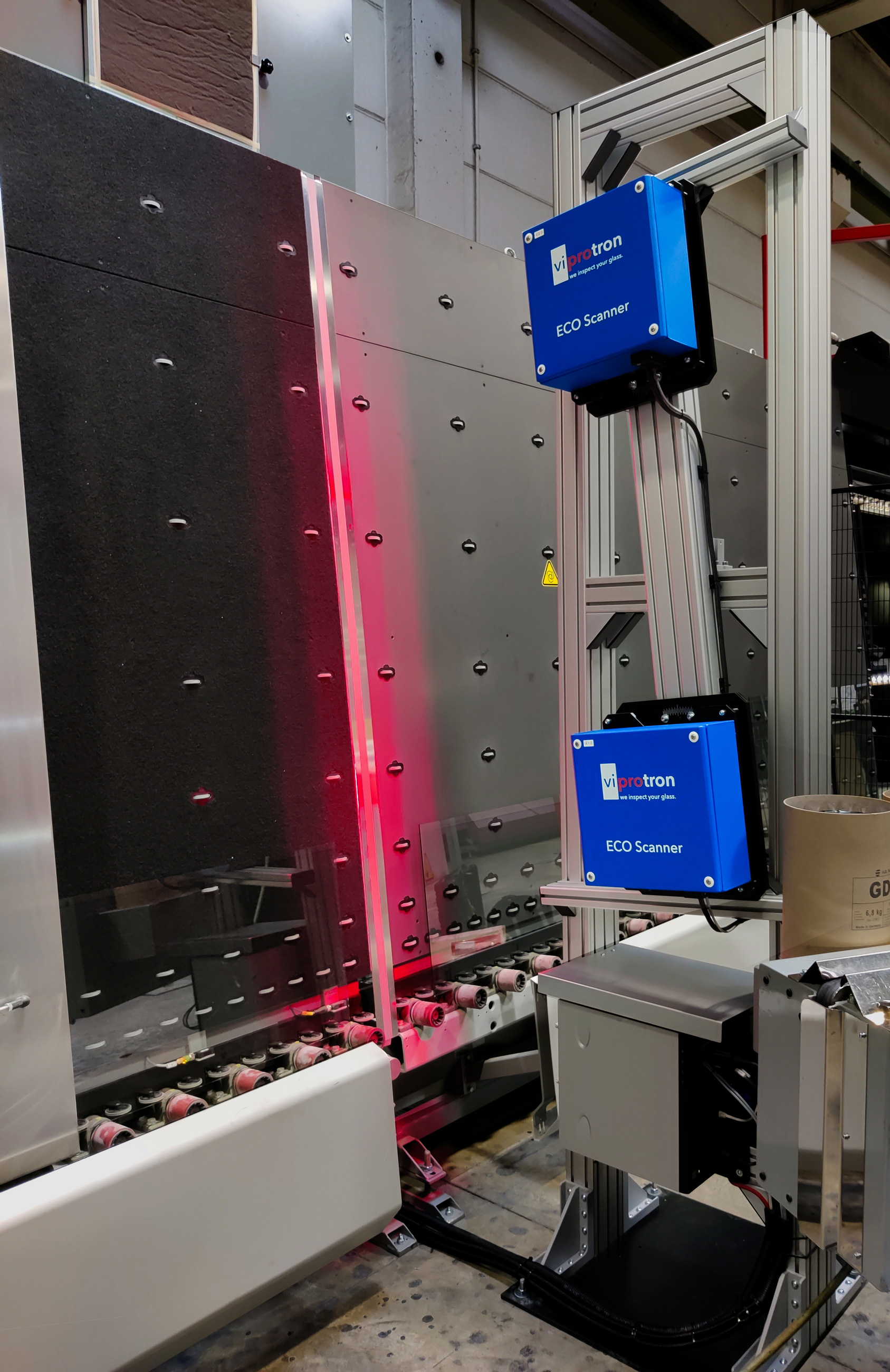

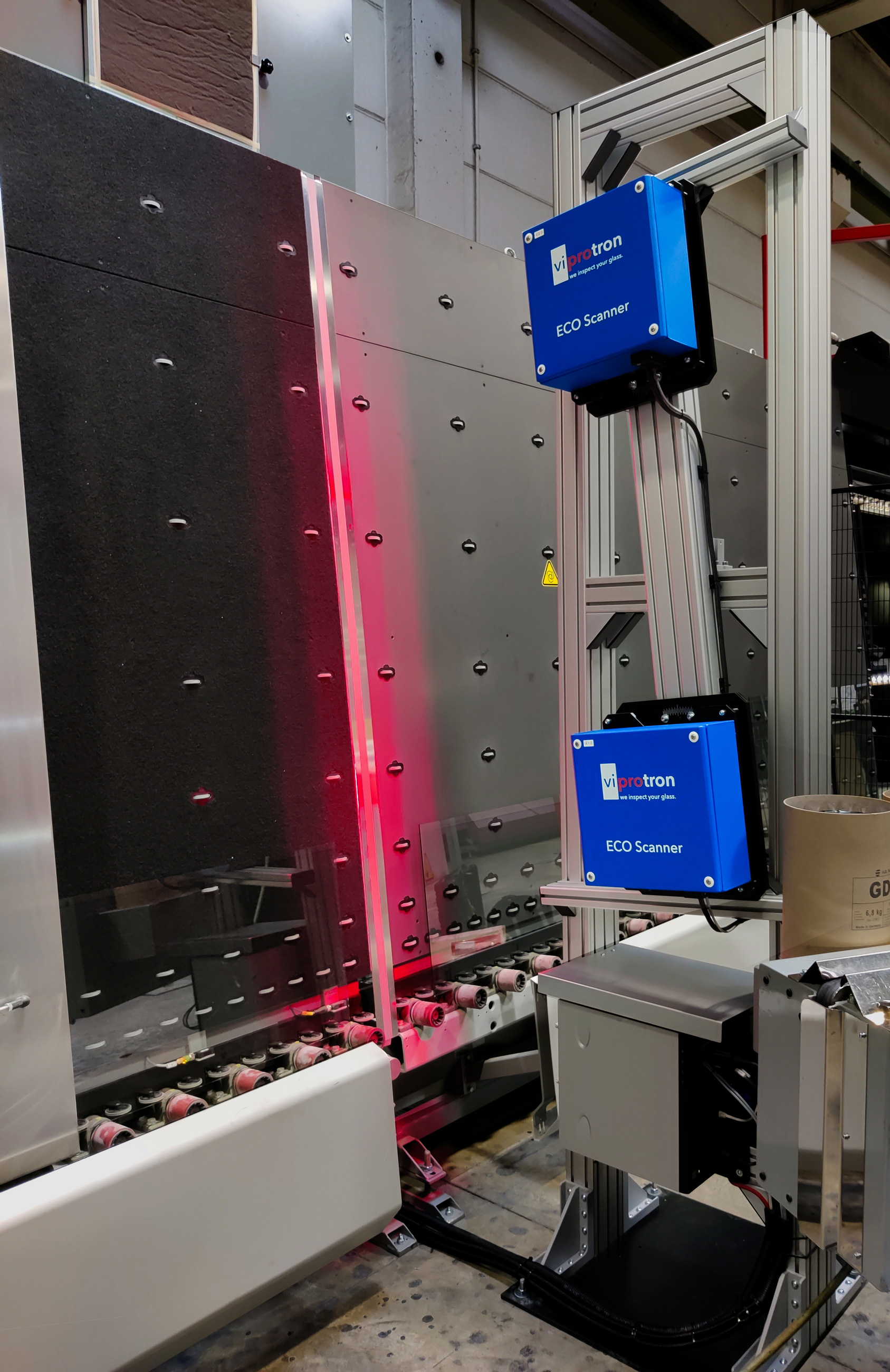

With its attractive price, the ECO Scanner is the first and only plug & play scanner to define a new category on the market and, as a pure brightfield application, has a truly unique position.

Plug & Play Scanner

Its innovative design makes it possible. The ECO Scanner can be easily integrated into existing and new production lines - whether vertical or horizontal! Since no gap is required in the production line and installation instructions are available, the customer can easily assemble the ECO Scanner themselves. As a customer, all you have to do in advance is to ensure that the construction for mounting the camera and illumination module is adapted to the production line. Viprotron provides drawings for this. Of course, Viprotron also delivers the complete package, if wanted.

Due to the very high level of standardization of the ECO Scanner and thanks to its revolutionary functional principle, a price level Scanner has become achievable that is significantly below that of the modular Quality. The ECO Scanner also offers an ideal solution for divided productions with several washing machines that do not allow central inspection of glasses. Because of its low price, it is possible to use several devices at the same time - and that with a total investment that quickly pays off.

The channels used

With its brightfield channel, the ECO Scanner detects all high-contrast defects (inclusions, bubbles, scratches, etc.) that must be detected according to EN 1279, ASTM C1036 or other international standards. This range of performance makes the ECO Scanner ideal for checking all glasses directly after washing. In this way you ensure good glass quality or can sort out defective glass before further expensive process steps.

The testing processes

The special feature here, however, is that the passage of light through the glass is not accompanied by a passage of light through the line, as it is the case with all other scanners that check in brightfield transmission. The light required for the inspection is sent from the camera side in the direction of the line and - from the camera's point of view - reflected behind the glass by an industrial reflective tape in the direction from which it came. The light shines through the passing glass and thus provides the necessary amount of light from behind.

Focus

- High contrast defects (bubbles, inclusions, scratches, etc.)

Modularly expandable

Although the ECO Scanner cannot be expanded with additional channels, it can be easily installed at a new location if it is no longer required at its previous location.

Options to

- Improvement of the workflow (e.g. traffic lights, packages for lami or IGU, etc.)

- Storage and use of data (dashboard, reports, archive)

Technical specifications

Unit height/width |

Up to 3.30 m as standard |

Design |

Horizontal or vertical |

Maximum glass sizes |

3.30 m x 6.00 m |

Glass types that can be tested |

Float, tinted glass, tempered, laminated, LowE, etc. |

Glass thicknesses |

3 to 19 mm |

Transport speed |

Up to 20 m/min optional up to 50 m/min |

FAQ

-

An installation wizard, documentation and videos are available for self-assembly. For three years these tools have been subject to constant improvement and supported continuous product improvements. However, in order not to leave you alone, a one-day installation support is optionally available with every purchase of the scanner, which will help you to carry out the installation yourself in the shortest possible time.

-

The basic concept of the ECO Scanner is a form of delivery that is as standardized as possible in order to enable a competitive price. This means that only the main components come from Viprotron and the peripherals either come from the customer's own warehouse or can be procured locally to minimize freight costs.

-

Due to the type and arrangement of the illumination, the ECO Scanner is designed for checking for defects in glasses that are in the transmission range of over 60% light transmission. Optionally, 53% light transmission is possible.

-

Unlike other brightfield scanners, no gap in the line is necessary. In this respect, the preparations descent to a minimum: the reflective tape must have a base to which it can be glued. This is usually the vertical or horizontal conveyor belt itself. It is important to ensure that the belt vibrates as little as possible when the pane is being transported. The necessary mount for installing the scanner components must either be purchased locally in advance by the customer according to the Viprotron drawings or ordered from Viprotron.

Factsheet ECO Scanner

The most important information and advantages of the Viprotron ECO scanner at a glance.

Factsheet Inspection Systems

The advantages of our scanner systems at a glance. Because the higher quality of your glasses makes the difference

Contact

You would like to coordinate a project with us or have questions about products and services? Then simply call us or send us an e-mail. We are looking forward to your message!

Contact details

Viprotron GmbH

Ostendstraße 17

64319 Pfungstadt

Germany

- Phone number

- +49 6157 986 380

- info@viprotron.de

Viprotron North America Inc.

7501 S. Jackson Gap Way

Aurora CO 80016 – USA

- Phone number

- +1 313 384 3855

- ric.schmidt@viprotron.com