Fabrication

The many possibilities of digital image processing make it possible to reliably check the multi-stage processes in the area of glass processing for quality issues. With our scanners, you can optimize your workflows in a process-safe manner. For example, behind a double-edger, a - linked - vertical grinding machine, a collecting belt. Everything behind a washing machine, when it comes to the detection of optical defects. Also without a washing machine, if it is only a matter of measuring contour geometries, bore holes or cutouts. Then, however, with a conveyor belt specially designed for this function, which you can also order from Viprotron.

Inspection for optical defects

- Task

In order not to burden the furnace or other subsequent stages (printing, insulating glass, etc.) in your production with possible defective panes, you want to inspect the panes after edge and surface processing. You want to use several scanners there if necessary, an inspection according to standards or visual guidelines (EN 1279 I, ASTM C 1036, etc.) is sufficient for you and at the same time you do not want to overstretch your budget?

- Solution

Our ECO scanner, which inspects according to international standards, can help you. The scanner can even be installed by yourself after a washing machine. We support the installations online and with documentations, videos and drawings. Of course, we also install the scanners for you on request, if you want to receive the usual service as with our other scanners.

- Task

As before, only inspection according to standard is not sufficient!

- Lösung

High-performance inspection by the Quality Scanner 3D.

The scanner is placed after the washing machine. There it reliably detects all types of glass defects. In the inspection station, the system stops defective glass and visualizes the defects clearly and precisely via the monitor and the defect pointer. Dirty glass can be saved with another cleaning process, defective glass is rejected. And this 24/7, if required. With the use of the Quality Scanner 3D, the cycle time of the production line can even be increased, since qualitatively perfect glass is not inspected again manually, but can pass through and the defect detection process itself is accelerated by the visualization via monitor and Defect Pointer.

Measurement of contours, holes and cutouts

- Task

You still have several manual processes in the area of fabricating and want to improve the delivery quality there?

- Solution

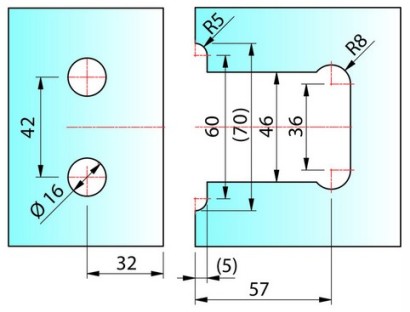

The Quality Checker SG measures the slice and checks it against a dxf. The dxf data are loaded from your PPS system. Afterwards, the sheet to be inspected travels through the Quality Checker SG on a calibrated inspection belt. The loaded data is matched against the dxf and deviations are detected. This includes the contour geometry, number of holes, hole positions and diameters, cutouts.

Since the Quality Checker SG works in the patented telecentric brightfield, it can also detect the high contrast defects such as scratches, bubbles or seeds. However, this should only be done after a washing machine to avoid the detection of pseudo defects.

Beginning of the value chain

Since the sheet has only taken a few process steps, faulty sheets can be detected here before expensive further processes are started.

Reports

All quality control results are logged and made available for internal or external purposes.

Process stability

The focus of the scanners on individual problem areas enables a significant improvement in process stability.

Contact

You would like to coordinate a project with us or have questions about products and services? Then simply call us or send us an e-mail. We are looking forward to your message!

Contact details

Viprotron GmbH

Ostendstraße 17

64319 Pfungstadt

Germany

- Phone number

- +49 6157 986 380

- info@viprotron.de

Viprotron North America Inc.

7501 S. Jackson Gap Way

Aurora CO 80016 – USA

- Phone number

- +1 313 384 3855

- ric.schmidt@viprotron.com