Insulating glass

Our systems, with their precise, camera-based image processing systems, reliably monitor the quality of the insulating glass during the various stages of production. They can be integrated at various points in the production lines.

Detection of glass defects on the single pane

- Task

You have no experience with scanners, you want to equip a new line with a limited budget, you want to retrofit an existing line or you are satisfied with an inspection according to standards or visual guidelines (EN 1279 I, ASTM C 1036, etc.)?

- Solution

Our ECO Scanner, which inspects according to international standards, can help you. The scanner can even be installed in the insulating glass line by yourself. So you save time and costs and are well prepared for the entry into the scanner technology. We support the installation online and through documentation, videos and drawings. Of course, we will also set up the scanner for you if you wish to receive the usual service as with our other scanners.

- Task

Despite a good inspection station, do you have too many optical defects in or on the glass?

- Solution

Objective and constant control over the complete production time with the Quality Scanner 3D.

The scanner is placed in the insulating glass line after the washing machine. There, it reliably detects all types of glass defects: In the inspection station, the system stops defective glass and visualizes the defects clearly and precisely via the monitor and the Defect Pointer. Dirty glass can be saved with an additional cleaning process, defective glass is rejected. And this 24/7, if required. With the use of the Quality Scanner 3D, the cycle time of the production line can even be decreased, since qualitatively perfect glass is not inspected again manually, but can pass through and the defect detection is accelerated by the visualization via monitor and Defect Pointer.

Automation of the frame setting in the insulating glass line

- Task

You intend to replace the conventional frame setting process with an automated process.

- Solution

When using an automatic frame setter, a rolled spacer (Super Spacer, Swiss Spacer, etc.) or a thermoplastic extruder (TPS, TPA, etc.), the scanner used must not only be able to inspect as many glasses as possible, but also provide reliable and repeatable inspection results. In addition to all standard glasses, our Quality Scanner 3D can not only inspect special glasses such as completely or partially acid etched glasses or white matt laminated safety glass, but also provide unambiguous results due to the best classification (determination) of defects by far. After all, you don't want to stop your insulating glass line because of water drops on your glass, but because there are bubbles in the glass that will lead to later complaints.

Inspection of spacers, muntins, pressed in butyl and high-contrast defects in the visible area of the insulating glass

- Task

A final inspection of the finished insulating glass does not take place yet or takes place rather accidentally and avoidable defects are delivered.

- Solution

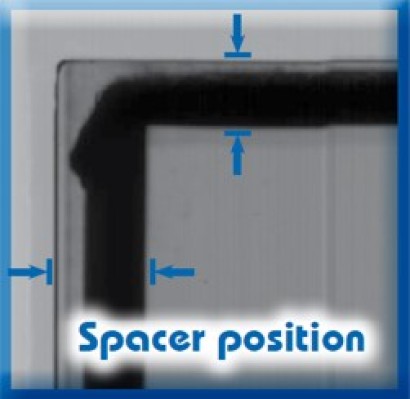

The long overdue 100% final inspection of your insulating glass is introduced! If the Quality Checker IG is integrated after the press, only glasses that meet the optical quality requirements of the company and its customers will leave the production line. The system checks the panes for scratches, checks whether butyl has penetrated into the visible area, and checks whether muntins and spacers have been correctly positioned in the double, triple, or multiple insulating glass.

Verification of anisotropies in the visible area of the insulating glass

- Task

Your customer expects the isotropy values of your insulating glass to reach a certain minimum value and additionally requires a corresponding report per insulating glass.

- Solution

The Anisotropy Scanner measures at normal production speed with polarized light in transmission and indicates whether the isotropy minimum target value of the entire unit has been reached or even exceeded. Although the isotropy values of the single individual panes are an excellent control and at the same time good information tool for furnace control, they provide only limited information about the effect of the individual anisotropy values in the entire insulating glass unit, especially if more than one pane of the insulating glass unit is tempered. Here, the anisotropy scanner integrated into an insulating glass line can remove all doubts. And, of course, the inspection software creates a separate results report for each insulating glass.

Your Benefits

Complete process control

All quality aspects of the processed single pane as well as the whole insulating glass are taken into account according to your requirements.

Reports

All quality control results are logged and made available for internal or external purposes.

Automation

The performance of the scanners and the width of the product range enable a precise focus on your tasks.

Contact

You would like to coordinate a project with us or have questions about products and services? Then simply call us or send us an e-mail. We are looking forward to your message!

Contact details

Viprotron GmbH

Ostendstraße 17

64319 Pfungstadt

Germany

- Phone number

- +49 6157 986 380

- info@viprotron.de

Viprotron North America Inc.

7501 S. Jackson Gap Way

Aurora CO 80016 – USA

- Phone number

- +1 313 384 3855

- ric.schmidt@viprotron.com