Lead The Way.

Sustainability is one of the major, indispensable issues of our time – in social, ecological and economic terms. Conservation of resources, climate and environmental friendliness and recycling of materials are important aspects in this context.

Glass pays tribute to all these aspects. It is made almost exclusively from natural raw materials that occur in sufficient quantities in nature and can largely be mined regionally. A benefit for the environment and climate. Glass as an environmentally friendly material can help to both gain or eliminate energy. However, the production of glass also requires a considerable amount of energy and should therefore not be wasted unnecessarily.

Did you know? The glass industry ranks 4th among the most energy-intensive industries in Germany (www.destatis.de).

Glass is 100 percent recyclable and can be reused an infinite number of times without any loss of quality. It can be returned to the melting process as often as required and processed into new products. Glass recycling therefore functions in a closed circular economy.

Recycled glass melts at lower temperatures than the raw materials needed to make glass. Energy requirements are reduced when old glass cullet is added. Melting down old glass thus protects the climate and saves raw materials such as quartz sand, soda ash and lime. However, the use of waste glass depends on the production-specific quality requirements for the purity of the cullet.

Panes that have thermal insulation or privacy coatings or are printed with ceramic colors or appear as laminated composites are not readily suitable for recycling. They must first be processed by appropriate companies. In the best case, the company's own cullet is used, which is produced as scrap during the company's own production. Before any energy-intensive further processing takes place.

This is not only for cost, but for environmental reasons as well. Every single material that is saved has a positive effect on CO2waste - regardless of whether it is a glass product, the raw materials themselves, ink in screen printing, or finishing processes in downstream processing. In this respect, flat glass companies have an increasing interest in voluntarily working more efficiently and thus more economically. The topic has developed into an important purchasing criteria for many consumers. Direct measurement of the carbon footprint is increasingly becoming a KPI and commitment.

You want to produce more efficiently?

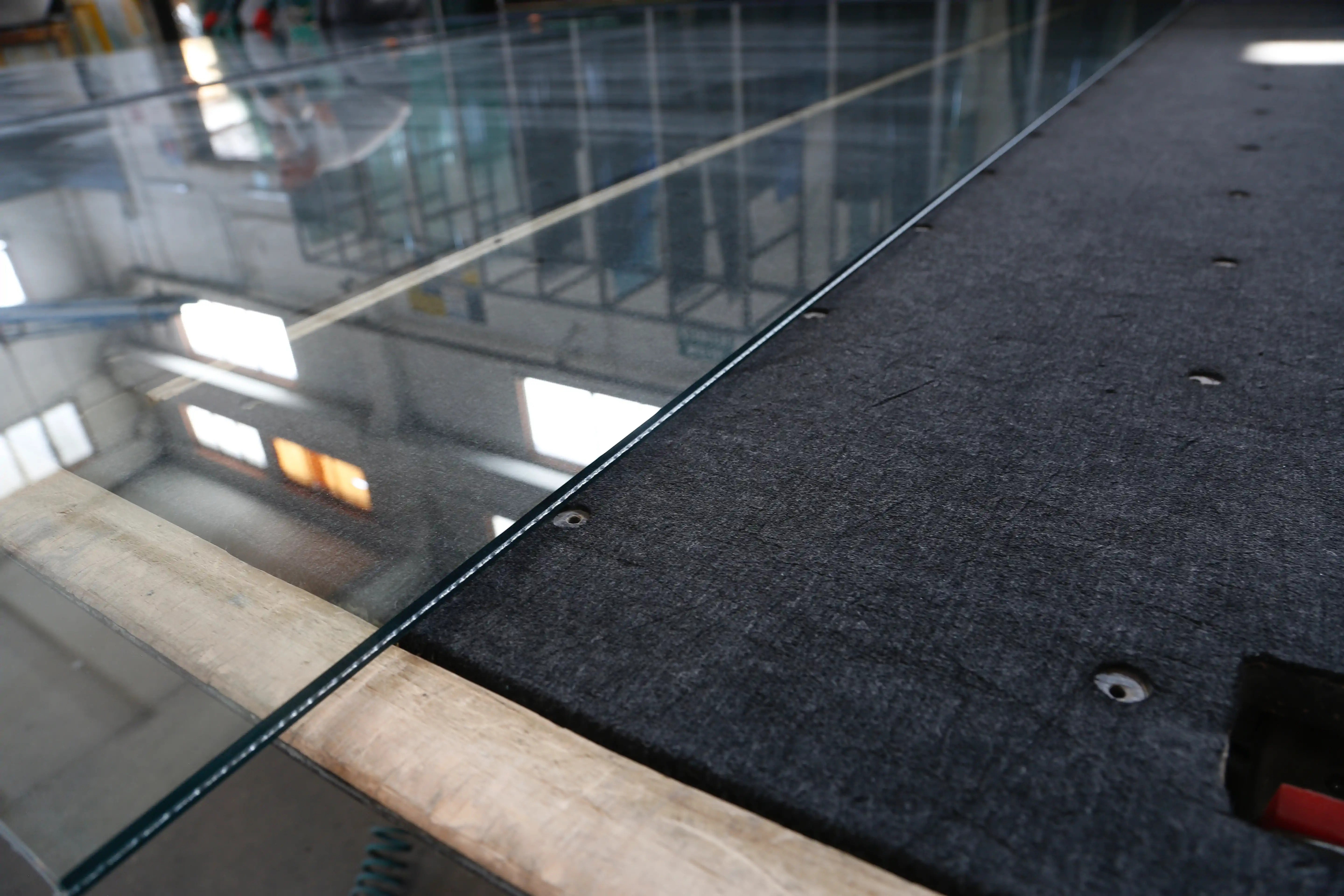

Viprotron scanners help to save resources in several ways. On the one hand, the reject rate of products can be reduced because the scanners detect defects before cutting, during the production process, or at the end of the production process. Defective slices are cleaned, reworked or sorted out for recycling.

On the other hand, materials that are used for further production processes (lami-foils, spacers, ceramic color, etc.) are completely saved. Comprehensive automation and thus continuous optimization of the processes are also supported by the scanners.

Savings at all levels

Carlton Glass in Singapore had to completely shut down and clean their furnace 3-4 times per month because defective panes exploded in it. During cleaning, production was at a standstill, after which the furnace had to be restarted with a high energy input. Apart from a monetary loss of up to 30,000 EU per failure, the value chain was gone and the waste of energy was unacceptable.

Edge damage and small bubbles that lead to explosions in the furnace (thermal shock) can be detected even with the "smallest" Viprotron scanner and defective panes can be ruled out. For Carlton Glass, the ECO Scanner meant a gain of 200 man-hours per month previously spent on cleaning. And a significant improvement in their environmental footprint.